Brass brushes

Commonly used to clean the following applications:

- Threaded

- Quick Connect

- 6,4 mm (1/4'')

- 7,9 mm (5/16'')

- 9,5 mm (3/8'')

- 11,1 mm (7/16'')

- 12,7 mm (1/2'')

- 14,3 mm (9/16'')

- 15,8 mm (5/8'')

- 17,5 mm (11/16'')

- 19,0 mm (3/4'')

- 20,6 mm (13/16'')

- 22,2 mm (7/8'')

- 23,8 mm (15/16'')

- 25,4 mm (1'')

Goodway® brass brushes (GTC-200B) are deisnged to remove light to mediumhard deposits from straight, smooth heat exchanger tubes. Use for ferrous and nonferrous tube metals. The above pricing is for a pack of 10 brushes.

Brass brushes

Goodway® brass brushes (GTC-200B) are designed to remove light to mediumhard deposits from straight, smooth heat exchanger tubes. Since the brushes are made out of brass material, they can be used for ferrous and nonferrous tube metals.

- Use these brushes to remove deposits, like: light rust and scaling.

Brass material

Because they are made from brass, these brushes are slightly more aggressive than standard nylon tube cleaning brushes. They are an ideal solution when Goodway® tube cleaning brushes – such as the spin-grit variants – are unable to completely remove deposits from heat exchanger tubes. Since brass is softer than stainless steel, it poses a lower risk of scratching the tube walls.

However, due to the harder nature of brass, these brushes generate more friction and place additional strain on the connected flexible shaft. For this reason, Goodway Benelux recommends using them for larger tube inner diameters, starting from 11,1 millimeters.

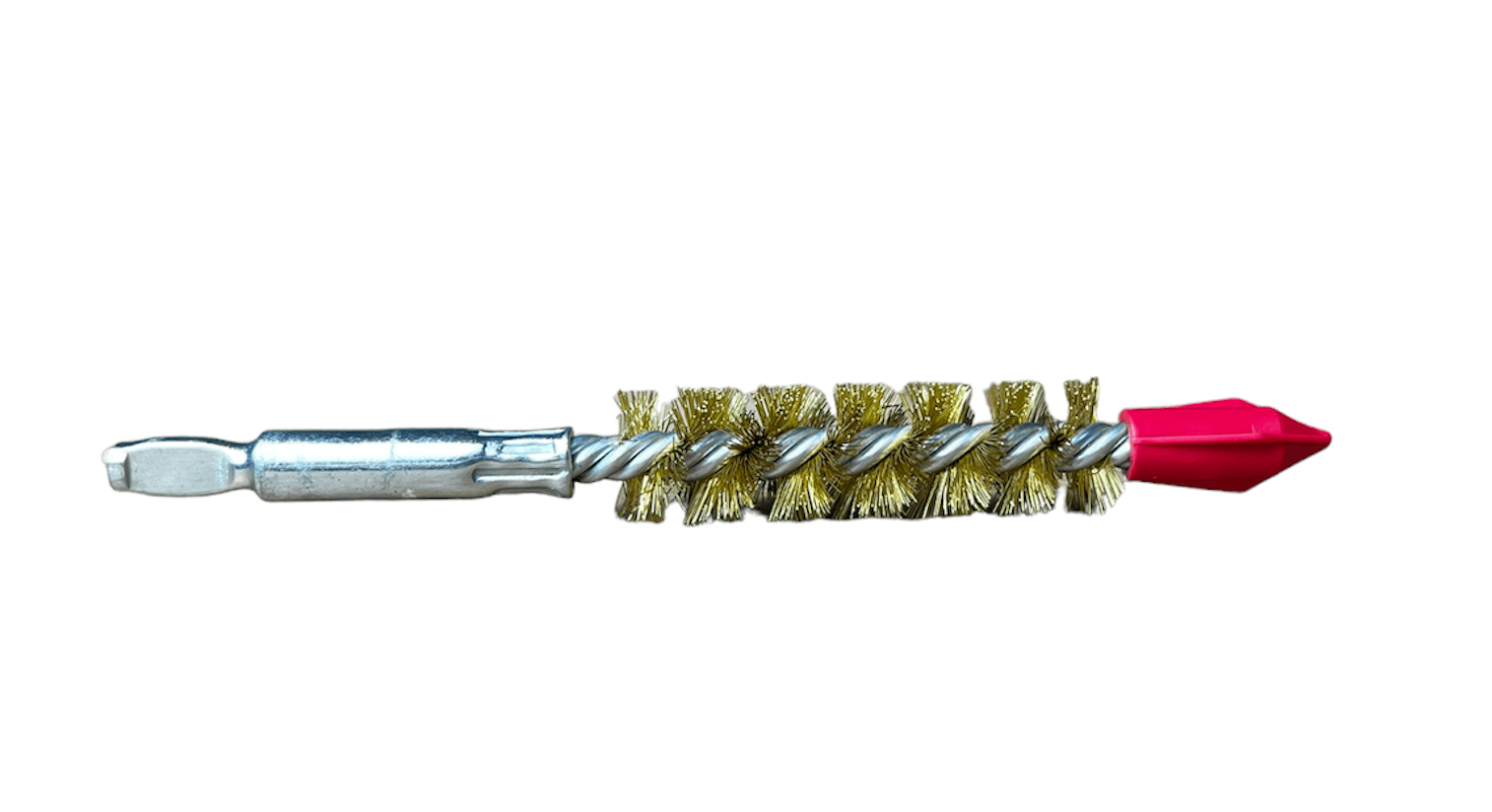

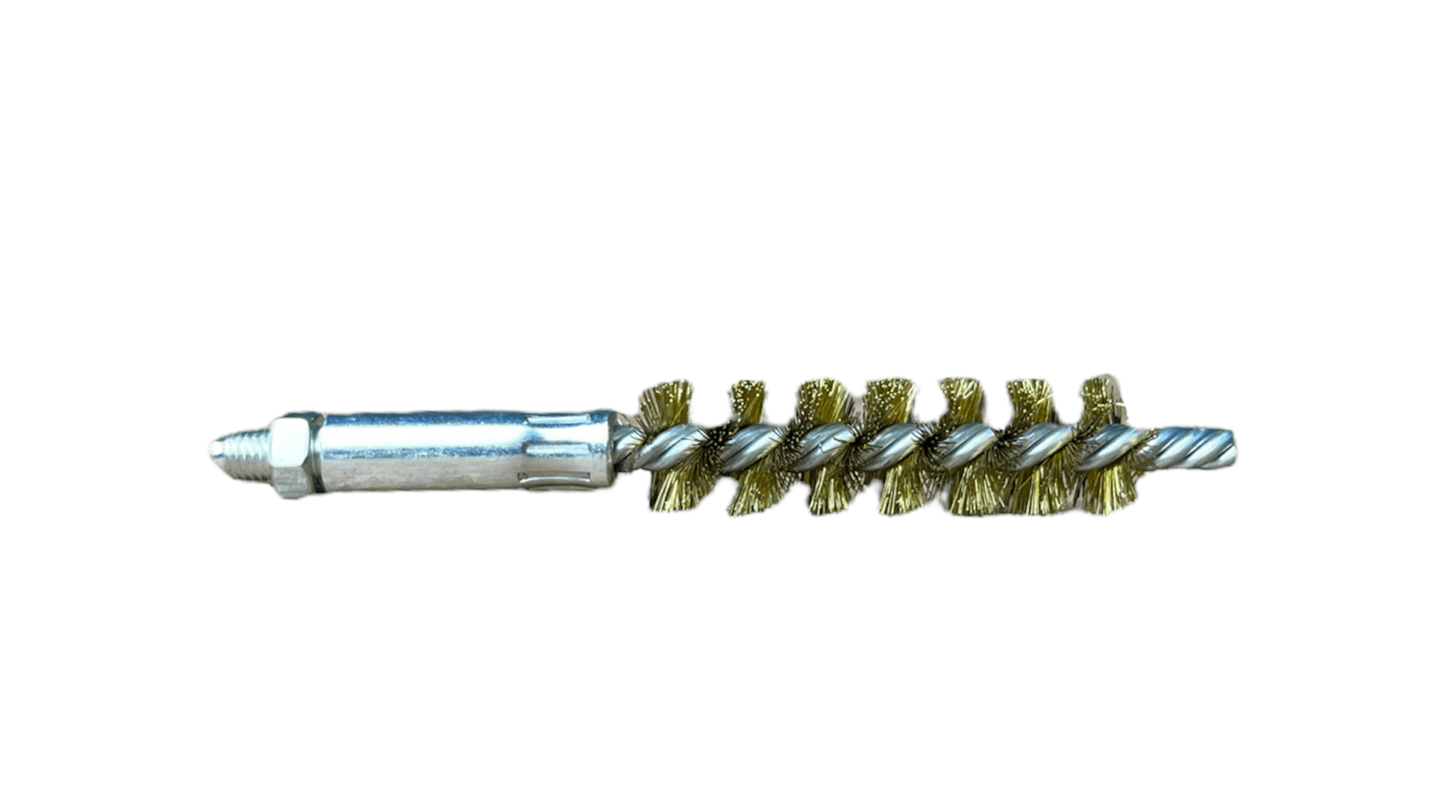

Threaded vs. Quick Connect

Goodway® brass brushes are available with either threaded or quick connect fittings. The right choice depends on your application:

- Quick Connect – Recommended for most chiller and heat exchanger cleaning applications. Enables bi-directional brush rotation for superior cleaning results. Best paired with machines such as: RAM-PRO, RAM-PRO-XL, and RAM-4.

- Threaded – Recommended for heavy-duty, industrial cleaning applications. Best paired with machines such as: AWT-100, AWT-100X, and RAM-4X.

Specifications Brass brushes

| Tube type application | Use for: smooth tubes only |

|---|---|

| Tube material compatibility | Use for: ferrous and nonferrous tube materials |

| Quick connect coupling | Use with machines: RAM-PRO, RAM-4, RAM-PRO-XL and RAM-5 |

| Threaded coupling | Use with machines: RAM-4X, AWT-100 and AWT-100X |

| Cleaning with water | Use with: blue flexible shafts |

| Cleaning without water | Use with: black flexible shafts |

| Pricing and supply | The website pricing is per pack of 10 brushes |